Professional road users have particular duties and responsibilities regarding the operation and maintenance of their vehicles.

These guides contain essential information necessary to the safe and efficient management of tyres fitted to commercial vehicles. They are addressed to vehicle operators in the UK and reflect UK regulations and operating conditions. The guidance may not be applicable in countries outside the UK. Equally, not all the advice may be applicable to specialist vehicles such as cranes or mobile plant.

Tyres can deteriorate with age which may show as cracking or crazing on the sidewall or in the grooves of the tread pattern. If in doubt consumers should consult a trained and qualified tyre professional to establish whether a tyre needs replacing. Deterioration may not always be visible and may also become apparent through increased noise or vibration.

Tyre ageing is not a function of the passage of time alone but rather the effect of cumulative exposure to adverse environmental and operational factors. Prolonged exposure to ozone or ultra-violet light can affect the natural and synthetic rubbers used in tyres. Tyre manufacturers incorporate additives to reduce this phenomenon. The flexing of the tyre in normal use helps the diffusion of these additives to the surface of the tyre where they act against the adverse effects of exposure to ozone and ultra-violet light. This diffusion process is greatly reduced in tyres fitted to vehicles that are used infrequently. Consequently, such tyres are more susceptible to degradation caused by adverse environmental factors than tyres on vehicles that are frequently used. Spare wheels and tyres on trailers are a case in point. Older or infrequently used tyres should be regularly inspected for early signs of deterioration.

Since tyre operating conditions and environmental exposure vary so widely, it is not possible to establish a universal age limit beyond which tyres are not suitable for further use.

Since the 1st February 2021 it has been illegal to use tyres more than 10 years old on the front steered axles of heavy goods vehicles, buses and coaches. This also applies to any wheel fitted in a single configuration on a minibus. In addition, all tyres on these vehicles will be required to display a date code.

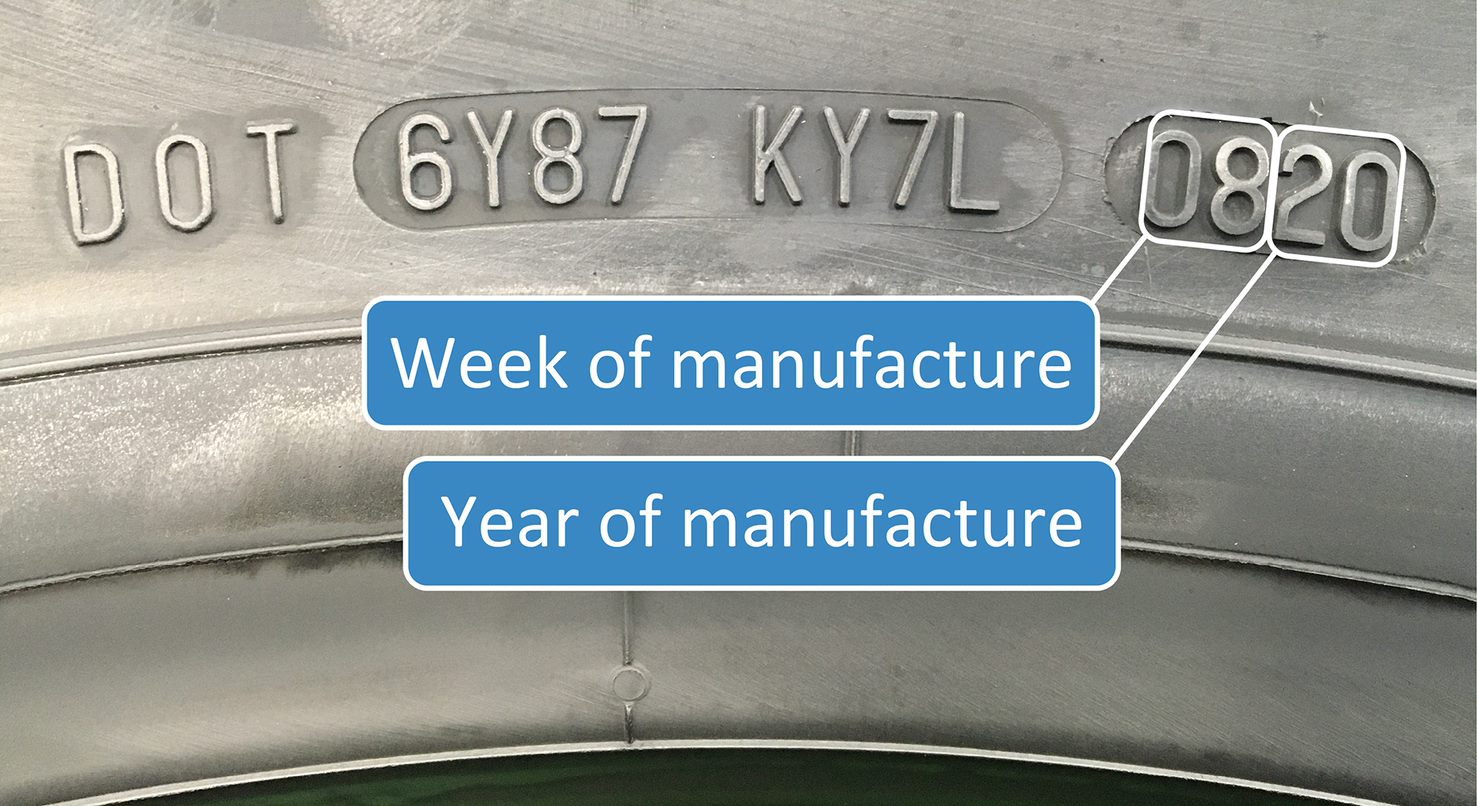

The date of manufacture of a new tyre can be determined from the code marked on the sidewall. The final four digits show the calendar week and the year of manufacture. The tyre in the photograph was manufactured in week 08 of 2020. Markings on retreaded tyres must show the most recent date of remanufacture. They may also show the date of original casing manufacture. Always refer to the latest date of manufacture, which will be the retread date.

The use of tyre filler does not constitute a repair: tyre filler should only be considered for localised cosmetic improvement where there is no penetration or ply damage. Only material particularly specified for use as tyre filler should be employed. Tyres with damage that extends to the reinforcement cords should be assessed by a qualified repair technician and, where appropriate, only repaired in accordance with BS AU 159g:2013.

Further information regarding tyre repairs is contained in the Guide to tyre management and maintenance on heavy vehicles, see above.