Truck & bus tyres can be retreaded two or three times and aircraft tyres many more. However, not all tyres have the necessary durability to be retreaded due to their design, materials or manufacturing quality. Only those with the right pedigree are sent for retreading.

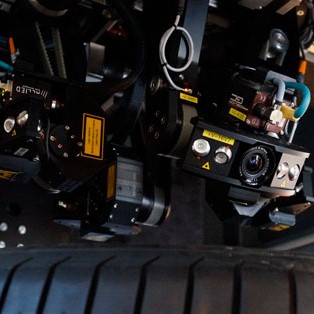

On arrival at the retreading factory the first stage of the process is a detailed visual inspection. This is then followed by internal examination by shearography (to detect separation between the components of the tyre) and x-ray (checking for defects in the steel reinforcement). Many candidate tyres have suffered unacceptable damage in use and are rejected and sent for recycling.

Initial Inspection

Shearography

Buffing

Quality Inspection

Building

Curing

Tyres that have passed initial inspection are then buffed to remove the remaining tread and prepare the surface of the tyre to receive the new rubber.

The buffed casing is then closely examined for any defects not revealed by initial inspection. Minor damage is also repaired at this stage before the casing is accepted for rebuilding.

It is at the building stage that the two retreading processes take different paths. In the cold cure process a pre-cured tread strip moulded with the new tread pattern is bonded onto the prepared casing using a thin veneer of rubber compound. In the hot cure process a layer of new uncured rubber compound is applied to the prepared casing.

In both processes curing requires the application of controlled heat and pressure during a carefully-controlled cycle. Both processes achieve a vulcanised bond between the prepared casing and the new tread. In the cold cure process the assembly is enclosed in a vacuum bag and cured for several hours in an autoclave at a relatively low temperature. In the hot cure process the assembly is placed in a tyre press where the tread pattern is moulded into the tyre and the new rubber is vulcanised at a relatively high temperature for typically less than an hour.

After curing the tyres are again subject to close visual examination and further testing. A high-voltage test checks for any pin-holes in the tyre and a high-pressure inflation test reveals any latent structural weakness. Only on successful completion of final acceptance testing is the tyre released to the market.

Retreaded tyres sold in the UK must by law be made in compliance with UN ECE Regulation 108 (Car tyres) or 109 (Commercial vehicle tyres). The retreading process and the operator must be certified by a national type approval authority (the Vehicle Certification Agency in the UK) and are subject to rigorous annual Conformity of Production verification by the type approval authority.