Tyres are a safety-critical part of every vehicle. They aren’t a fit and forget item: tyre performance can be heavily compromised by poor maintenance and under inflation. A little attention from time to time will save cost, breakdowns or worse.

If in doubt about the condition of your tyres, consult a trained and qualified tyre professional who will usually make an assessment without charge.

Users should inspect tyres monthly, checking for correct inflation pressure, tread depth, irregular wear, foreign objects or other signs of damage. A bulge on the sidewall is a clear indication the tyre’s internal structure has been damaged, usually by impacting a kerb or pothole; the tyre should be replaced urgently. If in doubt users should consult a tyre specialist.

UK regulations for car and van tyres require that the tread pattern must be at least 1.6 mm deep across the central three-quarters of the tread and around its entire circumference. Furthermore, no reinforcing cord should be exposed anywhere on the tyre.

However, not all pattern features fall within the legal definition of ‘Tread Pattern’. Any feature which is designed to wear out significantly before the main pattern is not subject to the minimum 1.6mm limit. Such features include tie bars and sipes.

A tyre’s inflation pressure is the largest single factor in determining how it will perform. It influences the tyre’s load carrying capacity, cornering power, service life and above all its safety. Under-inflation also causes increased fuel consumption and if prolonged and significant can cause structural damage, especially to low profile tyres.

Always maintain tyre pressures according to the vehicle or tyre manufacturer’s recommendations. These can be found within the vehicle handbook or on a placard mounted on the vehicle on a door pillar or near the fuel filler cap. Tyre pressures should be checked at least monthly and before any long journey with the tyre at ambient temperature.

The valve cap is the primary air seal and must always be fitted. The valve allows the tyre to be inflated and deflated; it should not be treated as a seal. Sealing valve caps should always be used and replaced as necessary.

Tyre Pressure Monitoring Systems (TPMS) alert the driver to tyre under-inflation. TPMS does not eliminate the need for the routine checking of tyre inflation and condition. Nor does it re-inflate the tyres when necessary.

Since November 2014 the fitment of TPMS has been mandatory on all new cars and light commercial vehicles sold in the UK. A wide range of retro-fit products is available for all vehicle types, including trailers and caravans, at increasingly competitive prices. Proven benefits include a significant reduction in tyre-related breakdowns, longer tyre life and improved fuel consumption.

There are two types of tyre pressure monitoring systems. The direct system uses radio sensors attached to the valve or mounted inside each of a vehicle’s tyres to measure the inflation pressure. The indirect system uses the Anti-lock Braking System (ABS) sensors to measure and compare the rotational speeds of the tyres from which tyre under inflation is deduced.

Direct systems may require replacement or maintenance of sensors due to damage or sensor battery failure. Instructions for mounting and demounting of tyres must be strictly observed to prevent damage to the sensor.

Indirect systems do not normally require maintenance. However, it is necessary to recalibrate an indirect system every time a tyre is changed. Always follow the instructions in the vehicle owner’s handbook.

Liquid sealants offer convenience but do not make a permanent repair; this requires an internal examination of the tyre by a competent technician prior to the application of suitable repair materials from the inside of the tyre.

Pre-puncture sealants

Where a pre-puncture sealant is used tyres should be frequently checked for penetration. This will avoid the aggravation of minor damage and allow the pursuit of a permanent repair at the earliest opportunity.

Post-puncture sealants and mobility kits

These are intended as “Get you home” measures only, enabling the vehicle to be driven home or to a tyre dealer where the damaged tyre can be properly inspected with a view to permanent repair.

Always carefully read and follow the manufacturer’s directions for use. These products have a finite storage life. Check from time to time that the expiry date on the sealant canister has not been passed as the product may not perform as intended: the puncture may not be sealed or re-inflation may not be achieved correctly.

Important notes:

- Some aftermarket sealants may adversely react with the material of the rim, tyre or valve;

- Sealants applied through the valve may impair its function causing blockage or leakage, inhibiting routine pressure maintenance;

- Liquid sealants may damage or disrupt the operation of the electronic sensor inside the tyre in certain types of tyre pressure monitoring systems;

- Some sealants may be difficult to remove from the tyre making repair impossible.

Any damage to a tyre should be addressed urgently.

Some minor damage can be safely repaired; principally penetrations to the central tread area. However, the tyre must not be repaired if there is any evidence of having been run in a severely underinflated condition. Equally, repairs to the shoulders or sidewalls, other than for cosmetic damage, may not assure the structural integrity of the tyre and are not approved.

Suitability for repair can only be determined following a complete inspection of the tyre both internally and externally. Tyre repairs should be carried out by trained and qualified professionals in compliance with the latest British standard BS AU 159g:2013. A permanent puncture repair requires the application of suitable repair materials from the inside of the tyre.

Post-puncture sealants and mobility kits do not constitute a permanent repair. They are intended as “Get you home” measures only, enabling the vehicle to be driven home or to a tyre dealer where the damaged tyre can be properly inspected with a view to permanent repair.

Repair of self-supporting “run-flat” tyres

As each tyre manufacturer may use different technical solutions to provide run flat capability, the view on repairing of self-supporting tyres varies across the industry. Reference should be made to tyre specialists or to the relevant tyre manufacturer for repair guidelines and to the vehicle owner’s handbook regarding the use of repaired tyres on the vehicle.

Tyres can deteriorate with age which may show as cracking or crazing on the sidewall or in the grooves of the tread pattern. If in doubt consumers should consult a trained and qualified tyre professional to establish whether a tyre needs replacing. Deterioration may not always be visible and may also become apparent through increased noise or vibration.

Tyre ageing is not a function of the passage of time alone but rather the effect of cumulative exposure to adverse environmental and operational factors. Prolonged exposure to ozone or ultra-violet light can affect the natural and synthetic rubbers used in tyres. Tyre manufacturers incorporate additives to reduce this phenomenon. The flexing of the tyre in normal use helps the diffusion of these additives to the surface of the tyre where they act against the adverse effects of exposure to ozone and ultra-violet light. This diffusion process is greatly reduced in tyres fitted to vehicles that are used infrequently. Consequently, such tyres are more susceptible to degradation caused by adverse environmental factors than tyres on vehicles that are frequently used. Spare wheels and tyres on trailers and caravans are a case in point. Older or infrequently used tyres should be regularly inspected for early signs of deterioration.

Since tyre operating conditions and environmental exposure vary so widely, it is not possible to establish a universal age limit beyond which tyres are not suitable for further use. However, some tyre manufacturers recommend that car or van tyres over 10 years old should be withdrawn from service.

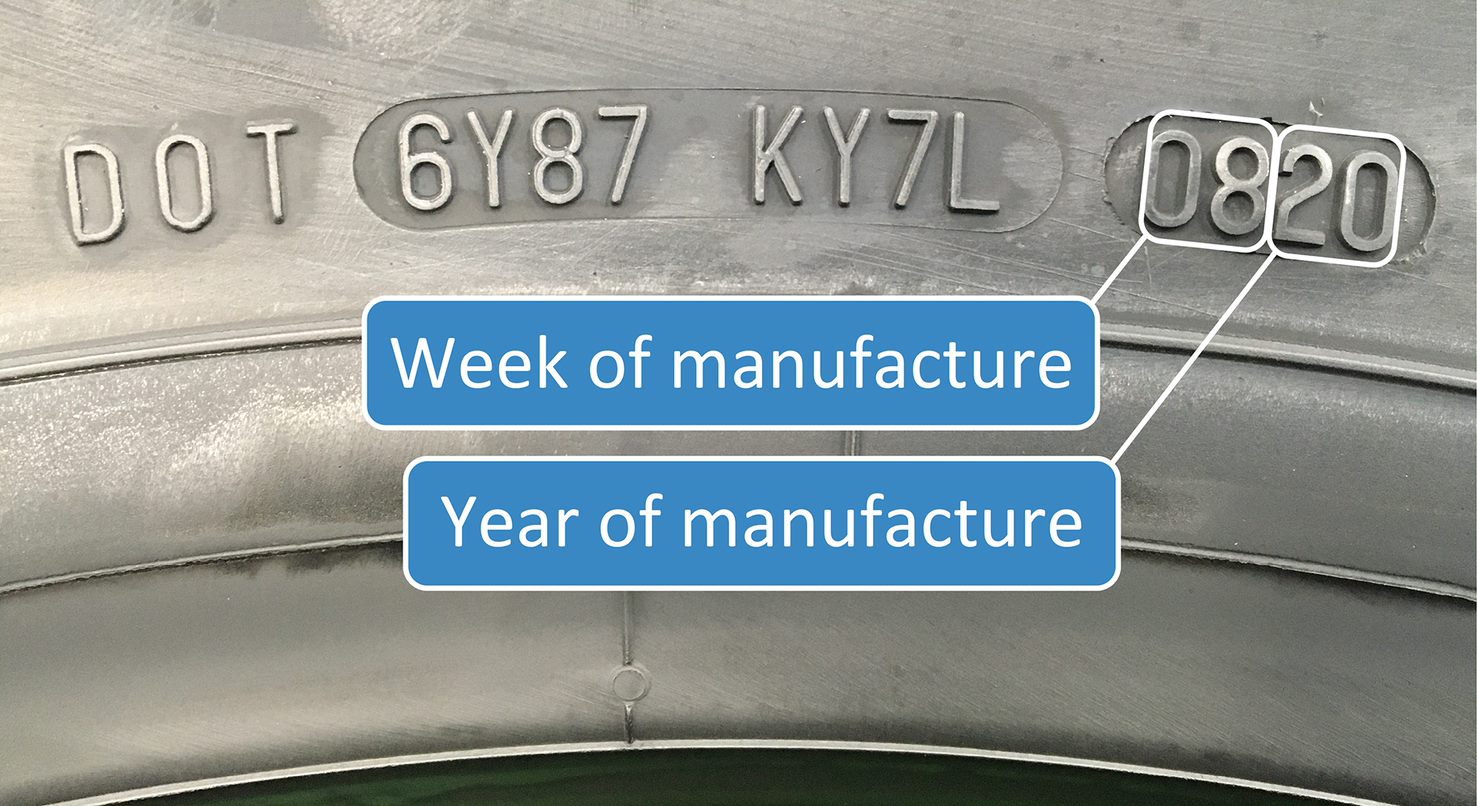

The date of manufacture of a new tyre can be determined from the code marked on the sidewall. The final four digits show the calendar week and the year of manufacture. The tyre in the photograph was manufactured in week 08 of 2020.

Sidewall dressing is a product applied to tyres to make them look shiny, clean and new. Claims that products will increase the tyre’s resistance to attack from ultra-violet light or ozone are unproven.

Sidewall dressing should never be applied to the tread as it can make the tread slippery. This is especially important for motorcycles.

Water or solvent-based?

There are two types of tyre dressings on the market: water-based and solvent based. Water-based dressings should not harm rubber over time. They are typically a combination of naturally occurring oils and synthetic polymers that provide a satin-like finish – very similar to the look of a new tyre. Most, if not all, water-based dressings are environmentally friendly.

Solvent-based silicone dressings leave a glossy film on the sidewall. Most solvent-based dressings contain petroleum distillates that over repeated use may lead to premature cracking of the tyre surface. They may also harm components such as vehicle paintwork and brakes if the product is over sprayed.

Health and safety

Always follow the manufacturer’s directions and wear protective gloves when applying solvent-based products. Also, because they are non-biodegradable, solvent-based tyre dressings with petroleum distillates should not be allowed to contaminate drains, waterways, rivers, etc.

The attraction of solvent-based tyre dressing products is that they give a glossy finish as opposed to the satin finish of water-based dressing, but are glossy tyres worth the hazards mentioned above?

Nitrogen inflation is widely used in specialist applications such as aircraft, earthmover and mining machinery, and in motor racing. The attraction of nitrogen as an inflation medium in these applications is that nitrogen contains no moisture. Moisture within the air in a tyre increases the rise in pressure as the tyre gets hot. This is important in motor racing where varying tyre pressures can significantly influence performance. However, the effect is minimal on road tyres in normal use.

Claims are made that tyre maintenance periods can be extended with nitrogen inflation. Although the diffusion rate of pure nitrogen is lower than for air, pressure loss can also occur through the valve or due to slow punctures. The tyre industry recommendation for regular pressure checks applies regardless of whether the tyre is inflated with nitrogen or air.

‘Topping up’ a nitrogen-inflated tyre using conventional compressed air will reduce or even negate the claimed benefits. Users of nitrogen must accept that tyre pressure maintenance will require a visit to a tyre dealer that has nitrogen equipment.

Some very high-performance road car manufacturers do promote the use of nitrogen tyre inflation. Owners of such cars should follow the vehicle manufacturer’s recommendations.

From time to time disinfectant wheel washes are imposed as part of measures to control the spread of disease. The use of disinfectants in this way can have a detrimental effect on tyres.

Some chemicals used in disinfectants can affect the rubber and reinforcement materials used in the construction of tyres. Any symptoms are likely to become evident in the medium to long term. Cracking or crazing will be visible if the exterior surface of the tyre has been affected. Where the tyre’s internal components have been affected, detection will be more difficult: if tyres with cuts or other damage exposing the cords have been exposed to disinfectant they should be replaced even if there are no external signs of degradation.

Where exposure to the disinfectant is unavoidable, it should be for the minimum possible time. The recommended treatment for contaminated tyres is to rinse them thoroughly with water as soon as practical after exposure. In cases where the disinfectant is not water soluble a small amount of detergent such as washing up liquid should be added to the rinse water.